MVR Mechanical Vapor Re-compression Technology

Technology Develop Background

1. For the problem of industrial waste water high concentration salt, it can be solved and reach zero carbon emission by evaporation technology, but the energy consumption during evaporation is very costly;

2. Sludge drying is an important step to realize the harmless and resourceful treatment of sludge. The existing drying process consumes a lot of energy;

3. Distillation is the main separation technology in chemical production, with a wide range and large scale, but generally has low thermal efficiency and high energy consumption;

4. MVR technology can use a small amount of electric energy to reuse the phase change heat of the evaporation, drying, and rectification process, reduce the energy consumption and operating costs of related industries dramatically;

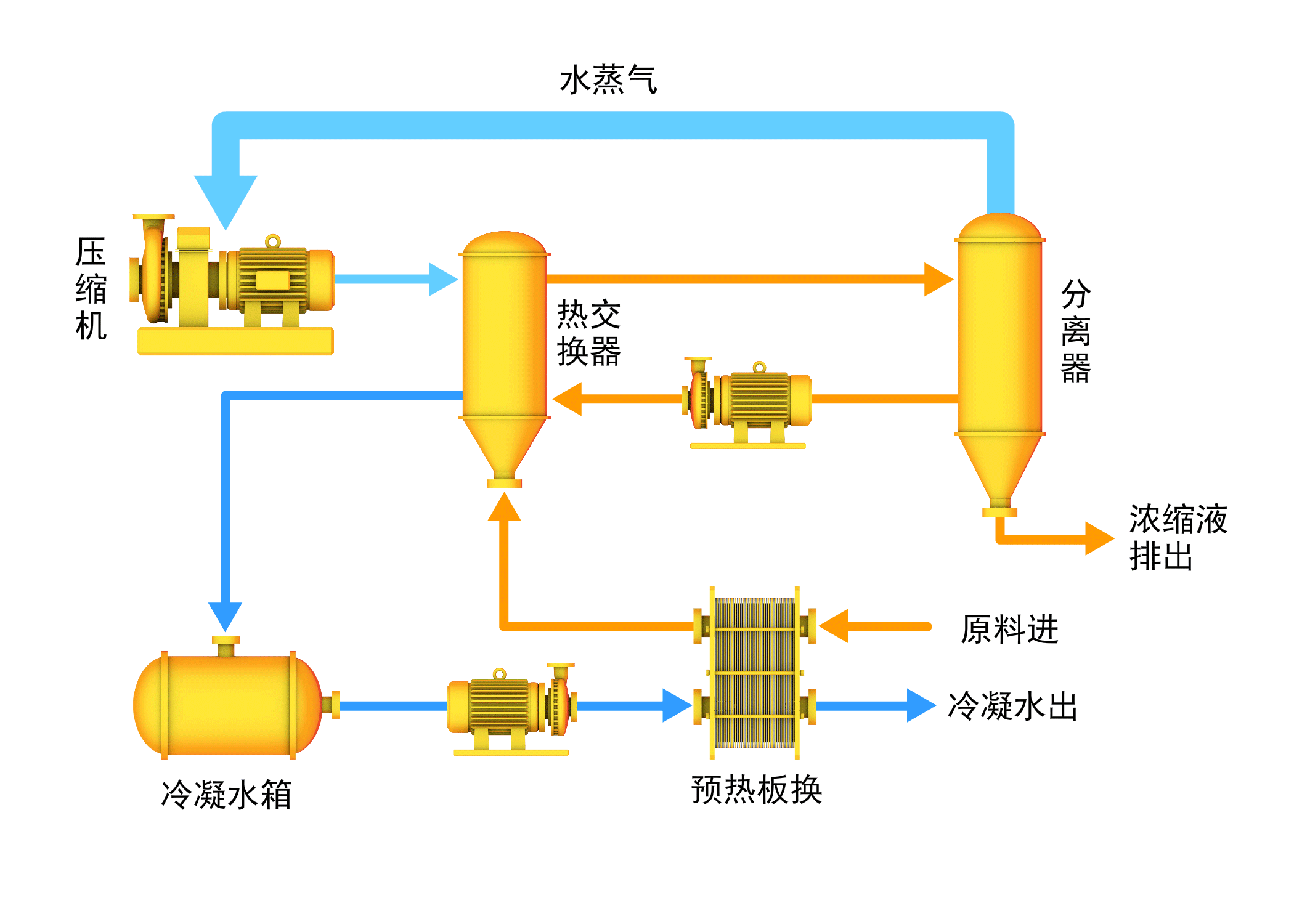

Technical Process Schematic

水蒸气 steam

压缩机 compressor

热交换器 heat exchanger

分离器 separator

原料进 source water inlet

冷凝水出 condensate water outlet

预热板换 Pre-heat exchanger

冷凝水箱 condensate water box

浓缩液排出 concentrate discharge

Application Instruction

MVR(Mechanical Vapor Re-compression) is an advanced evaporation technology in domestic and foreign evaporation field. This technology compresses the secondary steam generated in the evaporation process by a steam compressor, increases the pressure and temperature of the secondary steam, and returns it to the evaporator as a heat source to heat the original solution. This process makes full use of the latent heat of the secondary steam to achieve cyclic heating. The purpose of replacing fresh steam, saving a lot of energy, greatly reducing operating costs, and truly achieving the triple effect of energy saving, emission reduction and water saving.

MVR technology is widely used in the treatment of high-salt waste water and industrial production.

Technical Advantages

1. MVR evaporation crystallization technology can separate various salt crystals in waste water to obtain high-quality distilled water;

2. Using the principle of compression heat pump, replace the fresh new steam heat source with its own exhausted steam through a small amount of electricity consumption;

3. The energy consumption for evaporating one ton of waste water is as low as 20 kWh, and there is no other energy consumption;

4. Drying one ton of sludge (80% 40%), the energy consumption is as low as 100 kWh, and the comprehensive SMER>7;

5. In the rectification process, this technology uses 40-100 kWh of electricity to replace one ton of steam consumption in the original process.

Typical Process

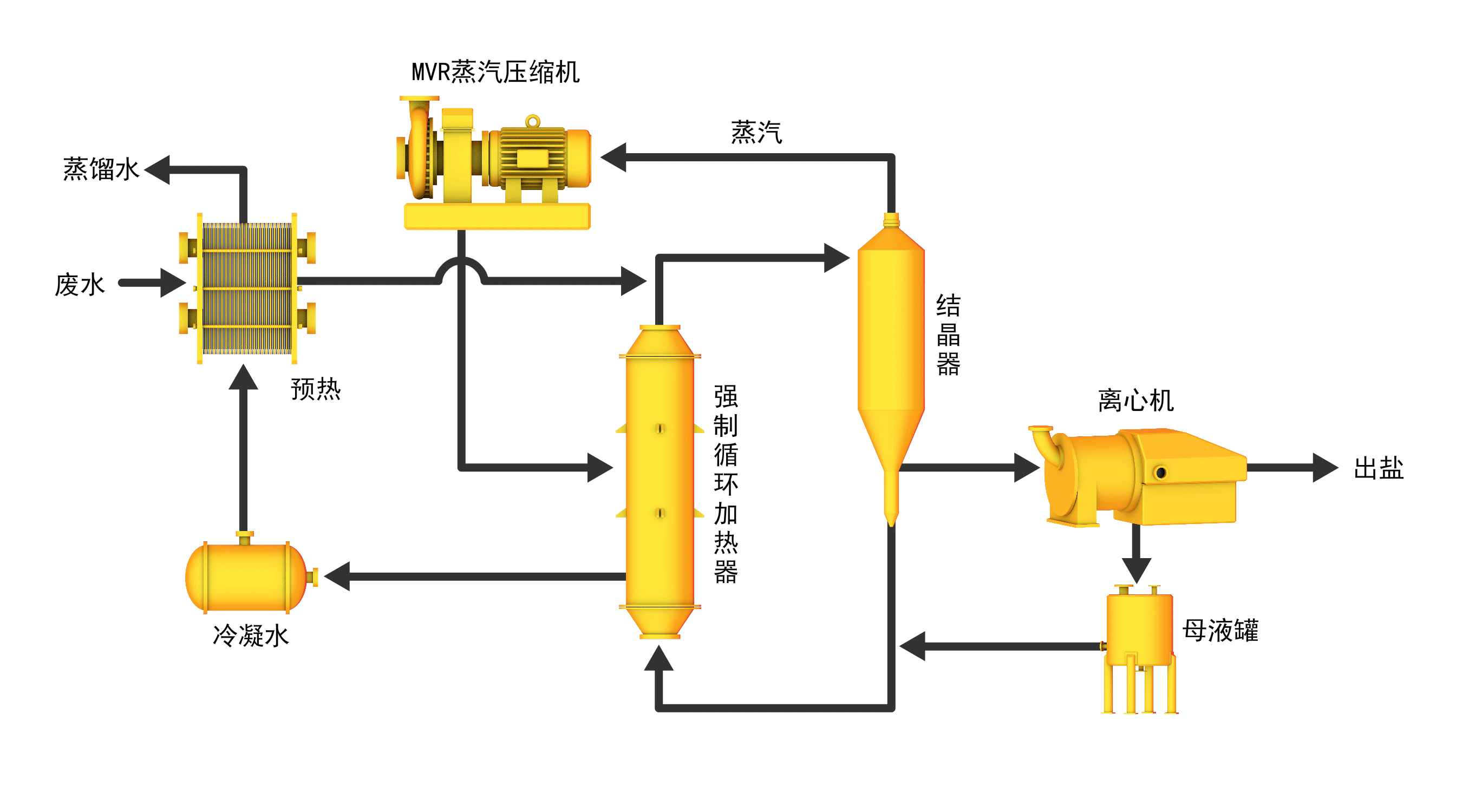

1. Evaporation (concentration) crystallization

蒸馏水Distilled water

废水Waste water

预热Preheat

冷凝水Condensate Water

强制循环加热器Forced circulation heater

MVR蒸汽压缩机 MVR steam compressor

蒸汽steam

结晶器Crystallizer

离心机Centrifuge

出盐Salt out

母液罐Mother liquor tank

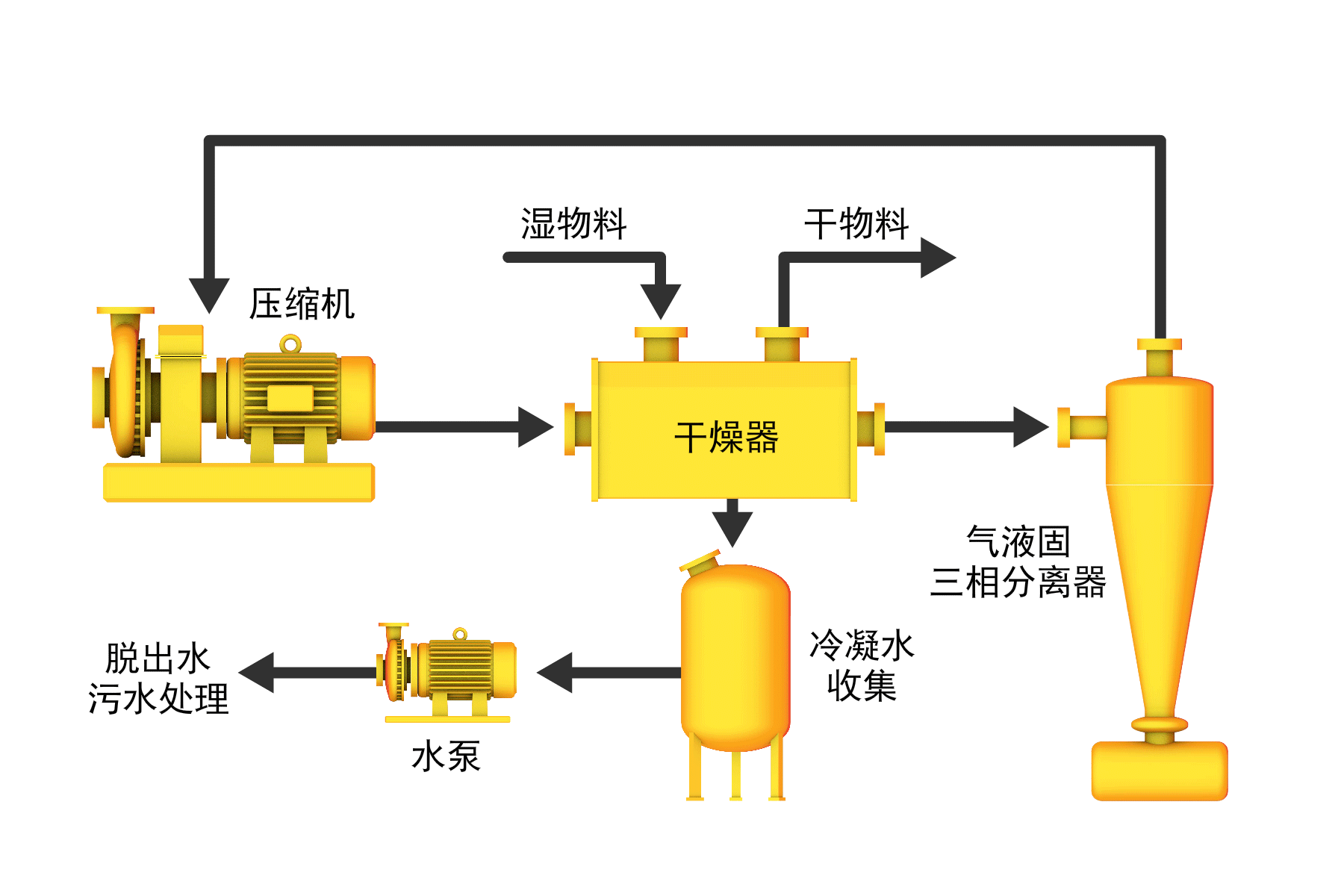

2、 Sludge drying

压缩机compressor

湿物料Wet material

干物料Dry material

干燥器Dryer

水泵Water pump

脱出水污水处理Sewage treatment

冷凝水收集Condensate collection

气液固三相分离器Gas-liquid-solid three-phase separator

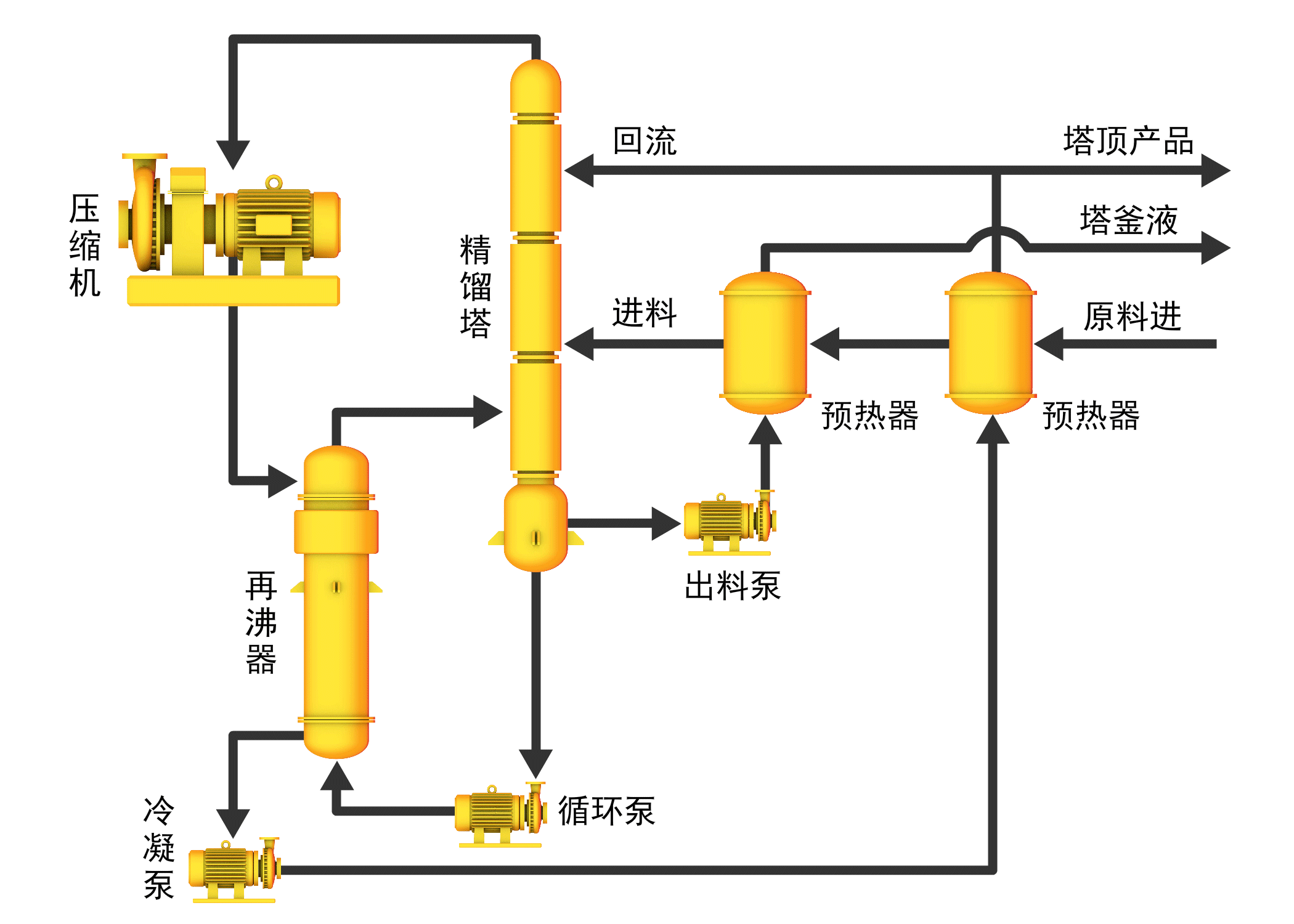

3、Rectification

压缩机compressor

冷凝泵Condensate pump

精馏塔Distillation tower

回流Backflow

进料Material feed

塔顶产品Tower top products

塔釜液Tower liquid

原料进Raw materials

预热器Preheater

出料泵Discharge pump

循环泵Circulation pump

再沸器Re-boiler

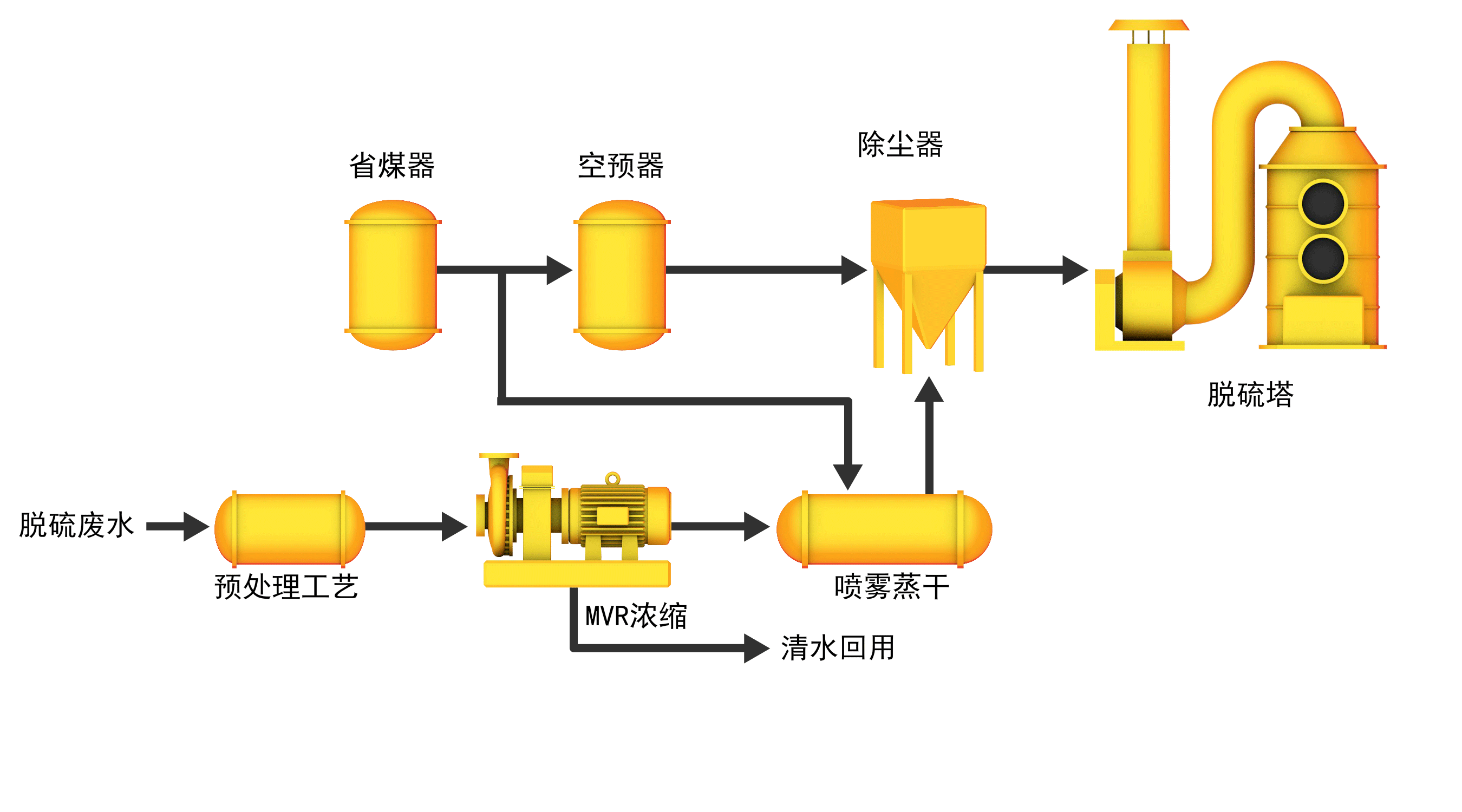

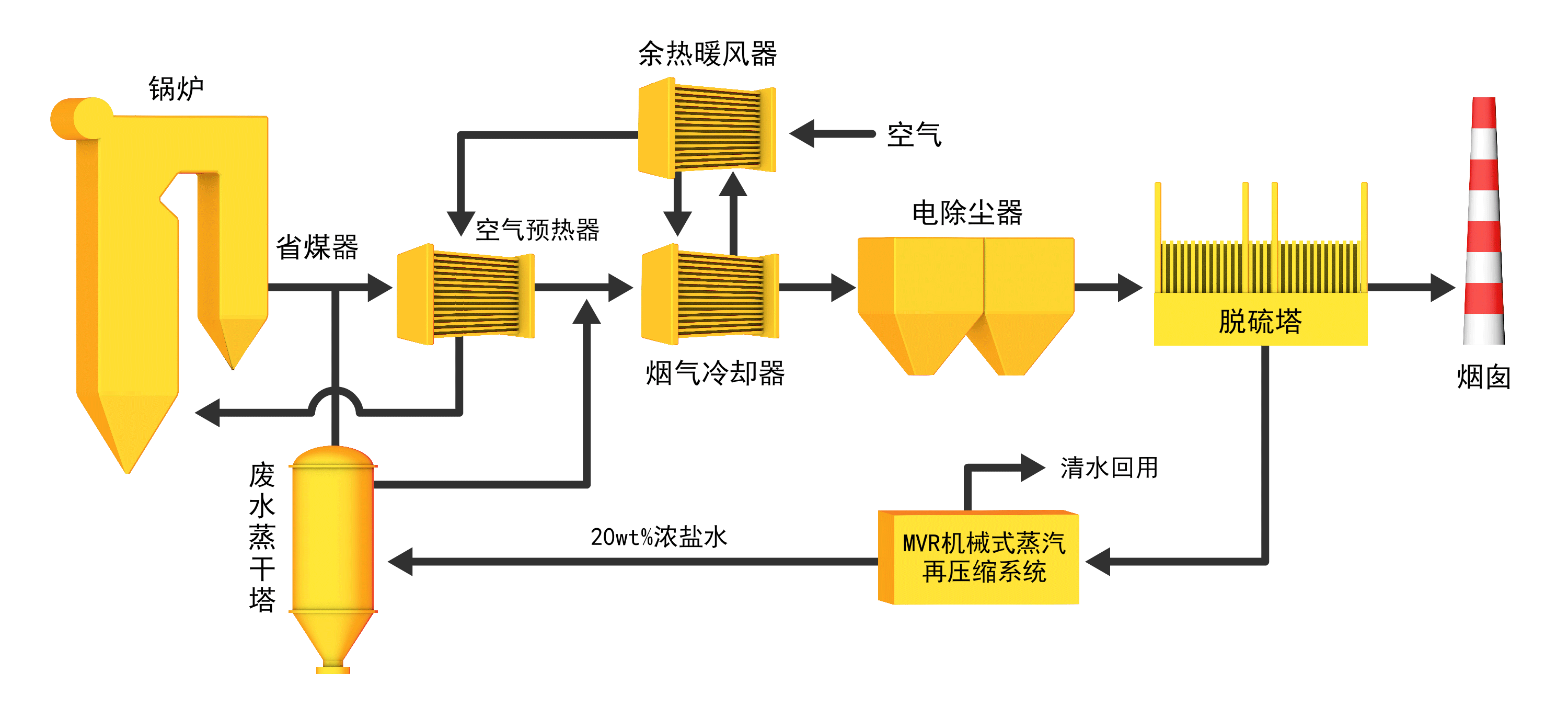

4、Zero discharge of desulfurization waste water:

锅炉Boiler

省煤器Economizer

废水蒸干塔Waste water evaporation tower

余热暖风器Residual heat heater

空气预热器Air preheater

空气Air

电除尘器Electric dust collector

烟气冷却器Flue gas cooler

20wt%浓盐水20wt% concentrated brine

5、MVR mechanical vapor recompression system

清水会用Water reuse

脱硫塔Desulfurization tower

烟囱Chimney

Background: